At Pollard Engineering, our expertise lies in both prototype and volume CNC milling and CNC lathe production. We employ cutting-edge machining centers, including renowned brands such as Mazak, Miyano, Muratec, Mori Seiki, and Hardinge.

Our commitment is to deliver high-precision machined components and equipment to a diverse range of industries.

From the demanding requirements of mining and oil sectors to the intricate needs of electronics and measurement applications, we ensure quality, reliability, and precision in every project we undertake.

BSI ISO 9001 "2015" standard

Overview of our services

INSPECTION AND QUALITY

A fully equipped Inspection department and a Quality accreditation of BSI ISO 9001 “2015” Standard approved.

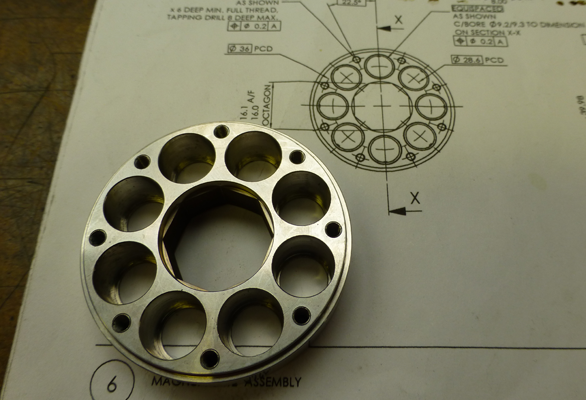

MACHINING CAPACITY

CNC Milling and CNC Lathe machining centres and special machinery including 5 axis milling turning capabilities.

STOCK HOLDING & ASSEMBLY

We are able to hold raw material and finished components on site and can offer a complete assembly service.

DESIGN FOR MANUFACTURING

Utilising latest machinery combined with CADCAM software for high precision components, R&D parts and assemblies.

EXOTIC MATERIALS

Specialists that are familiar in machining and handling both a wide range of standard and exotic materials.

APPROVED VENDORS

Can provide a turn key solution benefiting from a support structure to manage a variety of processes.

Need A Quote ?

If you have specific requirements, need a custom quote for a drawing or design, or seek further information about our comprehensive range of services, we invite you to share the details using the form provided.

Alternatively, feel free to reach out to us via telephone at +44 (0) 1684 274847 or by email at enquiries@pollardengineering.co.uk . We look forward to assisting you!

Get in touch

“The only way to do great work

is to love what you do”

“Coming together is a beginning.

Keeping together is progress. Working together is success.”

“We are resolute in our dedication to exceeding customer expectations, adhering to the principles of continuous improvement, striving for zero defects, and ensuring punctual deliveries.”