At Pollard Precision Engineering Limited, we take pride in our expertise in both prototype and volume CNC milling and CNC lathe production. Our commitment to excellence ensures that we deliver high-precision machined components and equipment to a diverse clientele across various industries, including:

- Mining: From critical mining equipment components to specialized machinery parts, we contribute to the efficiency and safety of mining operations.

- Oil Industry: Our precision-engineered components play a vital role in oil exploration, extraction, and refining processes.

- Electronics: We provide intricate components for electronic devices, ensuring reliability and performance.

- Measurement: Our dedication to precision extends to measurement equipment, supporting accurate data collection and analysis.

Our Comprehensive Offerings Include:

- CNC Milling: Whether it’s rapid prototyping or large-scale production, our CNC milling services guarantee precision and consistency.

- CNC Lathe Production: Our state-of-the-art CNC lathes create intricate parts with tight tolerances.

- Custom Components: We specialize in tailoring solutions to meet your specific requirements.

- Quality Assurance: Rigorous quality checks ensure that every component leaving our facility meets the highest standards.

Choose Pollard Precision Engineering Limited for unmatched precision, reliability, and personalized service. Contact us today to discuss your project needs.

INSPECTION AND QUALITY

A fully equipped Inspection department with various Automatic Digital Measuring systems and a Quality accreditation of BSI ISO 9001 “2015” Standard approved quality system since 1992 help strive towards zero defects.

MACHINING CAPACITY

Highly skilled team on a variety of CNC milling and CNC lathe machining centres and special machinery, including 5 axis milling turning machinery, all of which is complemented and supported by a wide range of manual machines.

STOCK HOLDING & ASSEMBLY

We have the capability to hold stock of raw material and also finished components on site. Combine this with our assembly facilities we are able to assemble multiple parts in one place as part of a dedicated and complete service.

DESIGN FOR MANUFACTURING

Using the latest machinery, CADCAM software, and our trained and skilled team enables us to specialise in the manufacture of high precision components, research and development parts and assemblies.

EXOTIC MATERIALS

Specialists in machining exotic materials and familiar with a wide range of materials including inconels, monel, duplex, titanium, berylium copper, toughmet, colsibro, all grades of stainless steel, brasses and aluminium.

APPROVED VENDORS

Can provide a turn key solution benefiting from a support structure to manage a variety of processes including honing, slurry deburring, ndt, welding, shotpeening, spark/wire eroding, heat treatments and a variety of hard-facings and coatings.

Need a quote ?

If you have specific requirements, need a custom quote for a drawing or design, or seek further information about our comprehensive range of services, we invite you to share the details using the form provided on our contact us page.

Alternatively, feel free to reach out to us via telephone at +44 (0) 1684 274847 or by email at enquiries@pollardengineering.co.uk . We look forward to assisting you!

Inspection and Quality

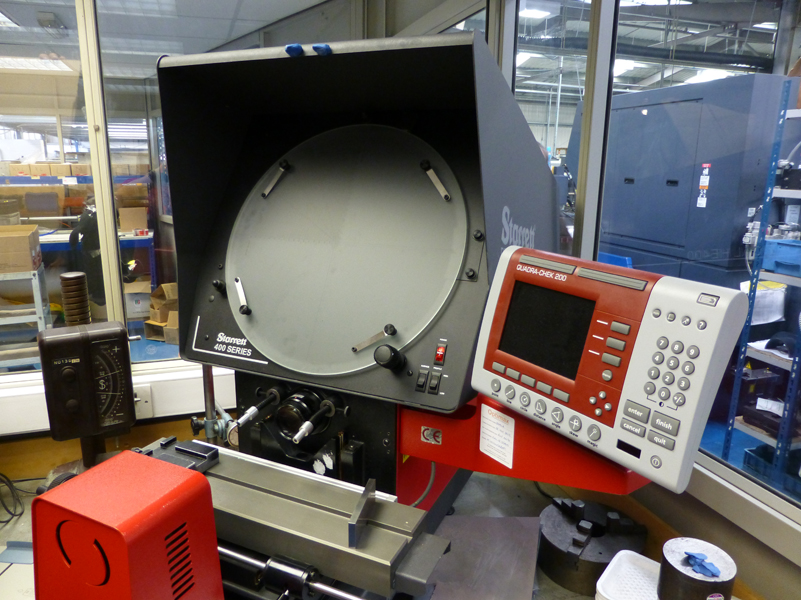

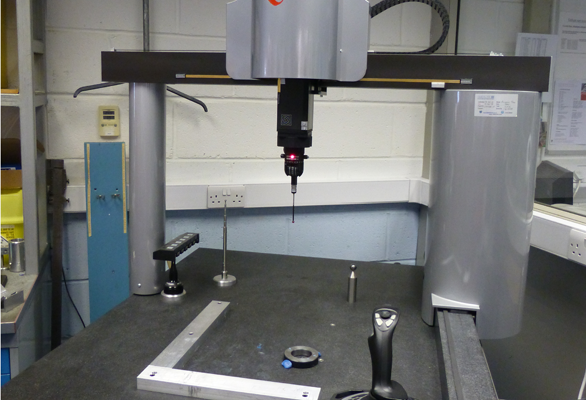

Our comprehensively equipped Inspection Department features a range of state-of-the-art Automatic Digital Measuring systems. Since 1992, we have maintained certification to the BSI ISO 9001:2015 Standard, demonstrating our commitment to quality management. Our relentless pursuit of excellence aims to achieve zero defects.

At Pollard Engineering Limited, our manufacturing facility boasts cutting-edge technology, including the latest Axiom Too 900CNC CMM (Coordinate Measuring Machine) and the Starrett HE400 Profile Projector. These advanced tools empower our fully equipped inspection department to meticulously assess product quality.

In addition, we maintain a comprehensive deburring and component assembly facility, ensuring seamless production processes. Our commitment to precision machining is unwavering, as we machine all types of materials to the tightest tolerances.

Recognizing that product excellence drives success, we prioritize customer satisfaction. Our skilled and motivated workforce, coupled with an effective quality control organization, ensures the highest level of service. We foster a quality-conscious management approach and actively promote continuous improvement throughout the company, incentivising our team to uphold our exceptional standards.

Our manufacturing capabilities encompass a wide range of precision services, including:

- Precision Machined Components: Our skilled team produces intricate components with meticulous attention to detail.

- CNC Milling and Turning, including Sliding Head CNC Turning: Leveraging advanced computer numerical control (CNC) technology, we achieve precise shapes and dimensions.

- Assembly: Our assembly processes ensure seamless integration of components for the final product.

- Manual and Semi-automatic Turning and Milling: Our experienced technicians handle turning and milling operations with precision.

- Anodizing: We enhance the durability and corrosion resistance of components through professional anodizing processes.

- Heat Treatments: Our controlled heat treatments optimize material properties for superior performance.

- Plating: We apply protective coatings to enhance surface properties and longevity.

- Delivery and Collection Service: Our efficient logistics ensure timely delivery and convenient collection.

- Manual and CNC Grinding: Our grinding expertise refines components to exact specifications.

- Honing: We achieve precise internal dimensions using specialized honing techniques."

These capabilities position us at the forefront of the precision machining market, ensuring exceptional quality and customer satisfaction.